Choosing the right tube bending machine

Choosing the right tube bending machine is crucial for the efficiency and quality of your production. However, with so many machine models and bending techniques to choose from, the decision can seem complex. In this article, we at Tinsel explain what you should look out for in order to find the right tube bending machine for your individual requirements.

1. Material type and pipe diameter

The material to be bent is the first factor you should consider. Different materials such as steel, aluminum, copper or plastic require different bending techniques and machine capacities. Some materials are harder and require more force or special tools, while others such as aluminum require gentler treatment to avoid deformation. The wall thickness of the pipes is particularly relevant for the required performance of the pipe bending machine.

The tube diameter also plays an important role. Machines have different capacities and not every pipe bending machine can handle large diameters. Make sure that the machine is suitable for the diameter of your pipes in order to achieve optimum results.

2. Bending radius and complexity of the bend

The type of bends you require will also influence the choice of machine. If tight radii or complex bends are required, you should choose a machine that has advanced bending techniques such as mandrel bending to avoid distortion or kinking. For simple bends without tight radii, a simpler rotary draw bending machine may be sufficient.

3. Production volume

Your production volume determines whether you need a manual, semi-automatic or fully automatic tube bending machine. For smaller production volumes or prototype production, a manual or semi-automatic machine may be sufficient. For large production volumes or series production, we recommend CNC-controlled machines that work precisely and efficiently and offer high repeat accuracy.

4. Level of automation

Depending on your requirements for efficiency and accuracy, you should consider how high the degree of automation of your machine should be. Modern CNC tube bending machines offer automated control and enable complex bends with high precision and speed. These machines minimize human intervention and are particularly suitable for series production and demanding projects.

5. Flexibility and variety of applications

Consider how flexible the machine needs to be. If you process different pipe sizes and materials or often switch between different bending angles and techniques, you need a machine that is easily adaptable. Some machines offer multi-functionality, while others are designed specifically for one technique.

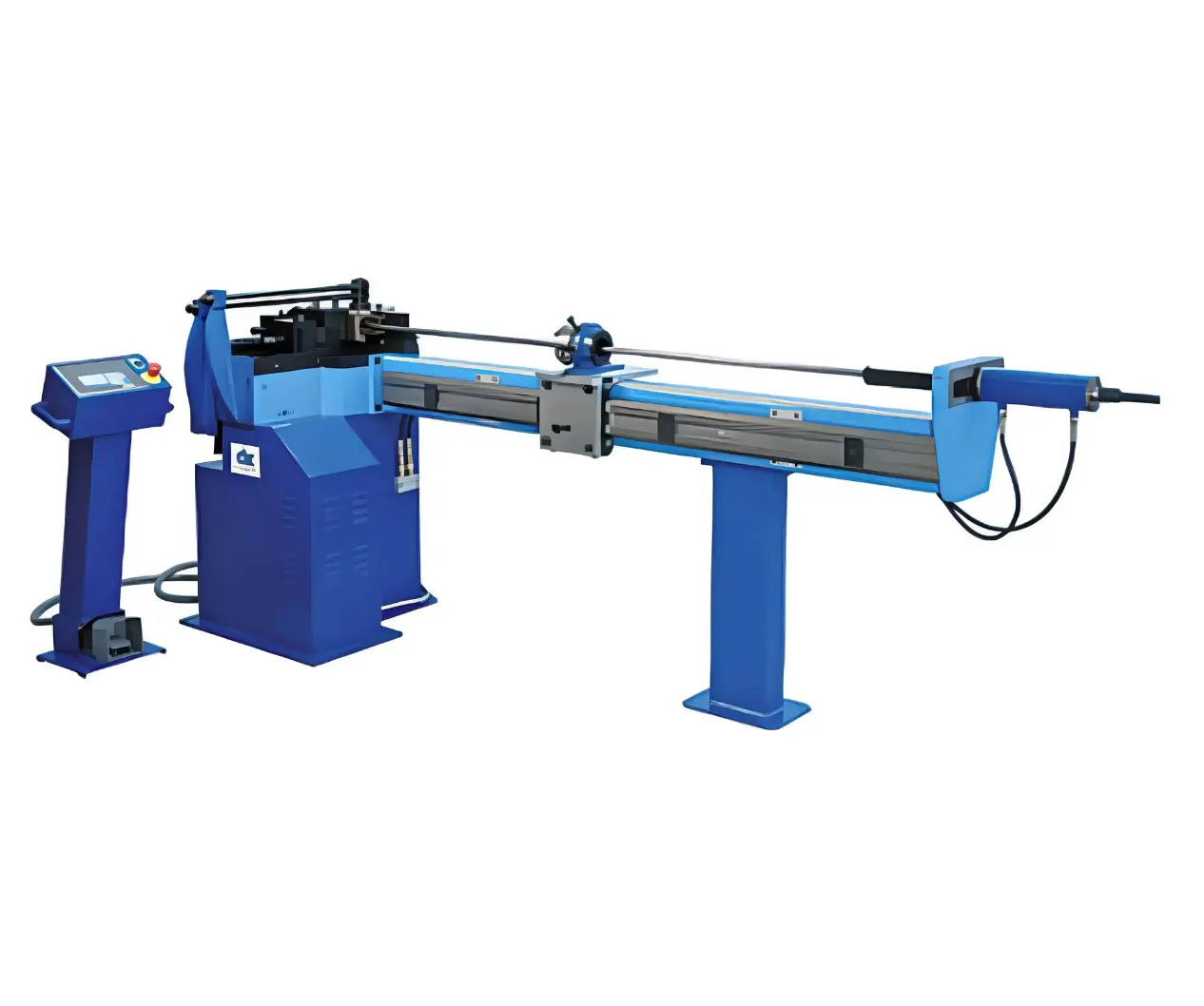

6. Space requirements and working environment

The space available in your production hall is another factor to consider. Tube bending machines vary considerably in size, and depending on the level of automation and capacity, some models require a lot of space. Also consider how well the machine can be integrated into your current workflow.

7. Service and maintenance

A tube bending machine is a long-term investment, so it is important to consider the service and maintenance requirements. Machines that require regular maintenance can cause additional costs and downtime. Look for models with good availability of spare parts and reliable after-sales service, such as Tinsel offers.

8. Budget

Last but not least, you need to consider the available budget. While fully automatic CNC machines deliver the best results, they are also the most expensive. For smaller operations or specific applications, it may make more sense to invest in a simpler machine that meets your current needs but also leaves room for future growth.

Our recommendation at Tinsel

At Tinsel, we offer comprehensive advice to help you find the tube bending machine that best suits your needs. Our machines cover a wide range of applications and bending techniques - from simple, manual machines to fully automated CNC systems. Whether you need tight radii, complex shapes or large quantities, we have the right solution.