The importance of material selection for tube bending

The choice of material is a key aspect in tube bending technology, which is decisive for the success of the bending process. Each material has specific properties that influence its behavior during bending - from elasticity and strength to dimensional stability. At Tinsel, we know how crucial the right choice of material is for the quality and efficiency of your production. In this article, we give you a detailed insight into the different materials and their importance for the tube bending process.

1. Why is the choice of material important?

Tube bending is a complex process in which it is important to maintain the structural integrity of the material while bending it into the desired shape. Choosing the wrong material can lead to deformation, fractures, kinks or other defects. The wrong choice of material can also lead to increased wear on the machines and affect the efficiency of the entire production process.

2. The most important materials for pipe bending

Depending on the application and industry, different materials are used for tube bending. Here is an overview of the most commonly used materials:

a) Steel

Characteristics:

- High structural robustness

- High resistance to wear and corrosion (especially stainless steel)

- Elastic, but retains its shape

Application:

Steel tubes are often used in the automotive and construction industries as they can withstand high loads. Due to its high strength, bending steel requires a robust machine and precise techniques such as mandrel bending.

b) Aluminum

Characteristics:

- Lightweight and corrosion-resistant

- Softer than steel

- Low density

Application:

Aluminum is ideal for applications where weight plays an important role, such as in aerospace or vehicle construction. As it is softer, it is easier to bend, but tends to deform without appropriate support. Aluminum can crack quickly if the bending parameters are not set optimally.

c) Copper

Characteristics:

- Excellent conductivity

- Soft and easy to bend

- Corrosion resistant

Application:

Copper is often used in plumbing and heating installations as well as in electrical systems. Thanks to its softness, it is easy to bend, but is also susceptible to crushing and kinking if not handled carefully.

d) Titanium

Characteristics:

- High strength with low weight

- Corrosion resistant

- More expensive than steel or aluminum

Application:

Titanium is often used in the aerospace and medical technology industries, where high strength and lightweight construction are required. Bending titanium requires special machines and techniques to avoid damaging the material.

e) Plastic

Characteristics:

- Flexible and lightweight

- Different degrees of stiffness depending on the type of plastic

- Corrosion and chemical resistant

Application:

Plastic pipes are often used in the chemical industry, water management and electrical installations. As plastics are more malleable than metals, they require specific bending techniques such as hot bending to prevent permanent deformation.

3. How does the material influence the bending process?

The choice of material influences which bending technique and which tube bending machine should be used. Here are some aspects you should consider:

a) Bending radius

A key factor is the minimum bending radius that a material can achieve without deformation. Softer materials such as copper or aluminum can bend tighter radii, while harder materials such as steel or titanium require larger radii to avoid deformation.

b) Bending resistance

The resistance that a material offers to bending varies greatly. High-strength materials such as steel require more force and robust machines. Softer materials such as aluminum require less force, but special supports to prevent collapse.

c) Springback

Another important criterion is springback, i.e. the phenomenon that a pipe springs back slightly after bending and straightens up again slightly. Materials such as steel have a higher springback, which must be taken into account when planning the bending angle.

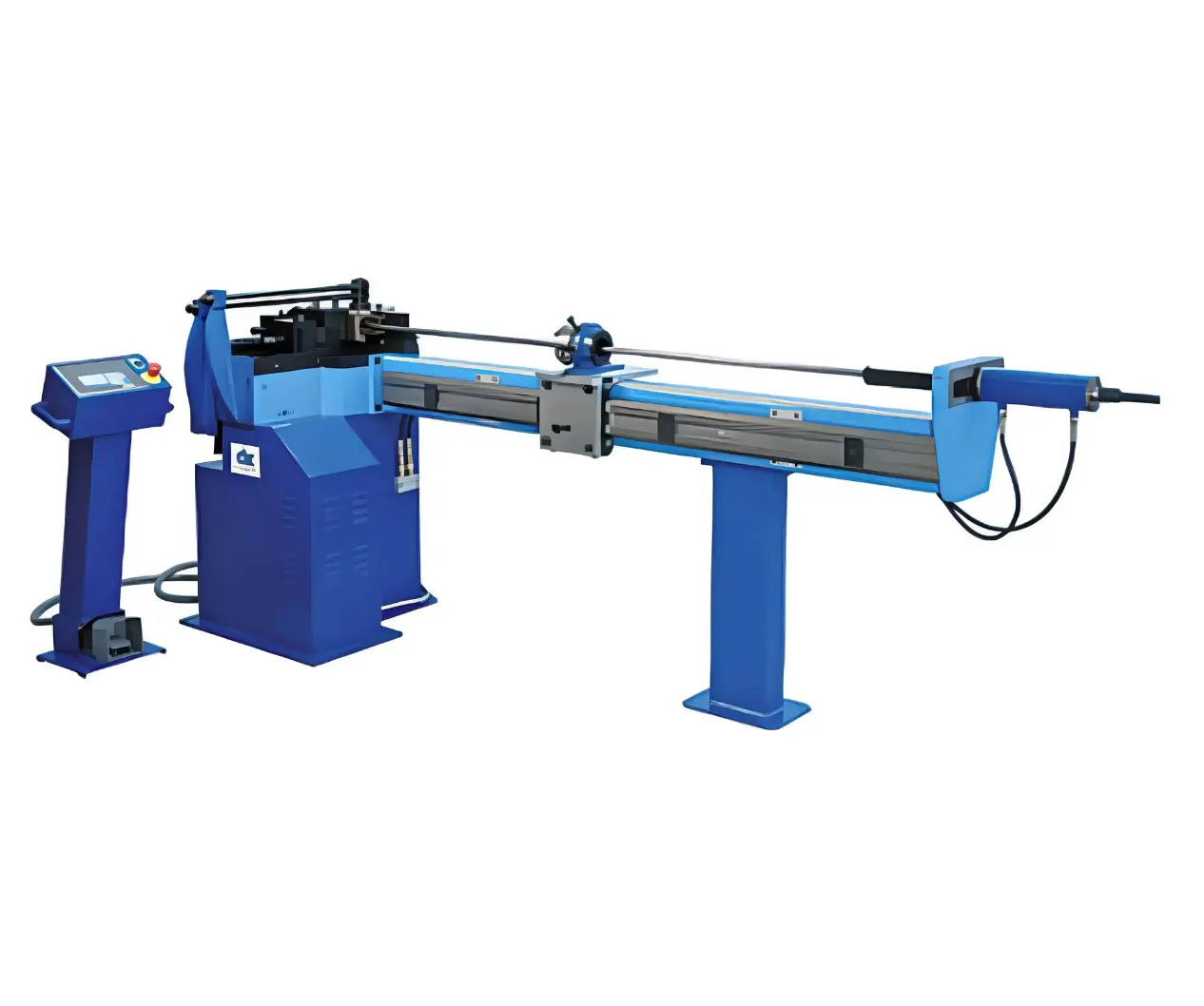

4. The right tube bending machine for different materials

Not every machine is suitable for every material. Here are some tips for choosing the right machine based on the material:

- Steel: Robust machines with high performance and mandrel bending technology to ensure kink-free bends.

- Aluminum: CNC-controlled machines that enable precise and smooth bends.

- Copper: Simpler machines with low bending force, ideal for rotary draw bending.

- Titanium: Special high-performance machines designed for high-strength materials.

- Plastic: Machines that offer hot bending options to keep the material flexible and prevent breakage.

5. Conclusion: How material selection increases production quality

The choice of material is crucial to the success of the bending process. A well-thought-out choice leads to cleaner bends, lower material losses and greater efficiency in production. Whether you work with steel, aluminum, copper or plastic - at Tinsel you will find the right tube bending machine for your material and your requirements. Our experts will help you find the optimum solution for your production.