Tube bending technology

Tube bending technology is a crucial process in many industries as it allows tubes to be formed into a variety of shapes used in the production of vehicles, machinery, furniture and even architectural structures. In this article, we at Tinsel, your expert in high-quality tube bending machines, would like to explain the basics of tube bending technology and its areas of application.

1 What is tube bending?

Tube bending refers to the process of bending pipes made of various materials - such as steel, aluminum, copper or plastic - into predetermined shapes. The task is to bend a pipe without damaging it, i.e. without crushing, breaking or deforming it.

2. Types of tube bending

There are several methods of tube bending, each of which is tailored to the specific requirements of the material, shape and intended use:

a) Mandrel bending

Mandrel bending involves inserting a mandrel into the pipe, which acts as a support. This technique prevents the tube from folding and deforming and is ideal for complex bends with tight radii.

b) Rotary draw bending

This method uses a bending mold to bend the tube to the desired angle. It is a precise technique that is used particularly in the automotive industry and in the manufacture of furniture frames.

c) Roll bending

In roll bending, the tube is guided between three rollers, which are gradually adjusted to create a uniform bend. This method is suitable for long, gentle bends and is often used in the construction industry.

d) Freeform bending

This method is more flexible and allows the tube to be bent without a fixed shape, which is particularly useful when producing prototypes or one-offs.

3. Advantages of tube bending

Tube bending machines enable high efficiency in production and offer many advantages:

- Material savings: As no weld seams are required, bending saves material and increases the strength of the structure.

- Aesthetics and functionality: Curved tubes offer both aesthetic and functional benefits. They enable elegant, seamless designs that are both stable and durable.

- Versatility: The variety of bending methods allows tubes to be produced in many different shapes and sizes for a wide range of applications.

4. Applications of tube bending technology

Tube bending technology is used in many industrial sectors, including:

- Automotive industry: Here, bent pipes are needed for exhaust systems, frames and chassis parts.

- Aviation and aerospace: Pipes are used for hydraulic systems and fuel lines.

- Furniture industry: Chair and table frames are often made of bent metal tubes that offer both stability and an attractive appearance.

- Construction: Curved tubes are used in architectural constructions, railings and steel structures.

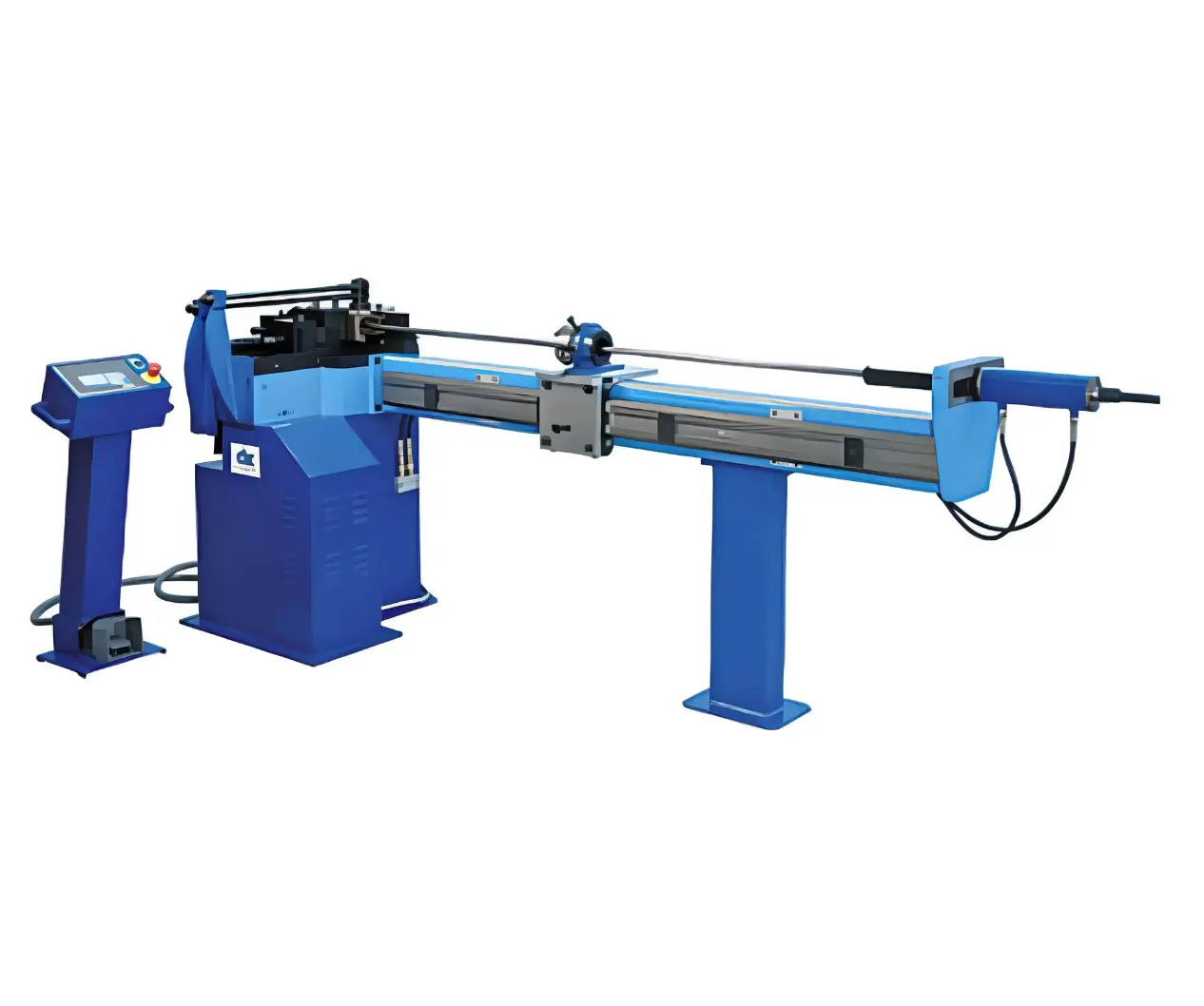

5 Our solution: Tube bending machines from Tinsel

At Tinsel, we offer you a wide range of tube bending machines that are tailored to your production requirements. Our machines are characterized by their precision, durability and user-friendliness. Whether mandrel bending, rotary draw bending or free-form bending - we offer the right machine for every application.

Our experts are on hand to help you choose the right technology. Let us work together to find the optimum solution for your production and benefit from the efficiency and versatility of our tube bending machines.