Hydraulic assembly machines using the pressure bending

Pressure bending is one of the main techniques used in modern metalworking and pipe installation. Through precise and repeatable bending operations, complex shapes and curves can be achieved with high accuracy without compromising the structural integrity of the material. Hydraulic assembly machines play a key role in this by transferring the required force to the material being bent. In this article, we take a look at different types of hydraulic assembly machines used in the pressure bending process. The focus is on machines with pairs of sliding clamps and special machines for bending pipes such as PEHD pipes (high-density polyethylene).

1. Manual bending machines with sliding bracket pair Mingori

These machines are typically used for smaller bending tasks where precision and manual control are crucial. The pair of sliding brackets ensures that the pipe or piece of metal is kept stable and evenly guided during bending. These machines are ideal for workshops and installation work where flexibility and mobility are required. Manual machines offer the advantage that the operator can directly control the speed and pressure of the bending process, which is particularly beneficial when working with delicate materials.

Advantages:

- High degree of control by the operator

- Cost-effective solution for smaller bending tasks

- Easy handling and maintenance

Application:

- Ideal for on-site installations where electrical power is not available

- Suitable for smaller pipe diameters and thinner metal parts

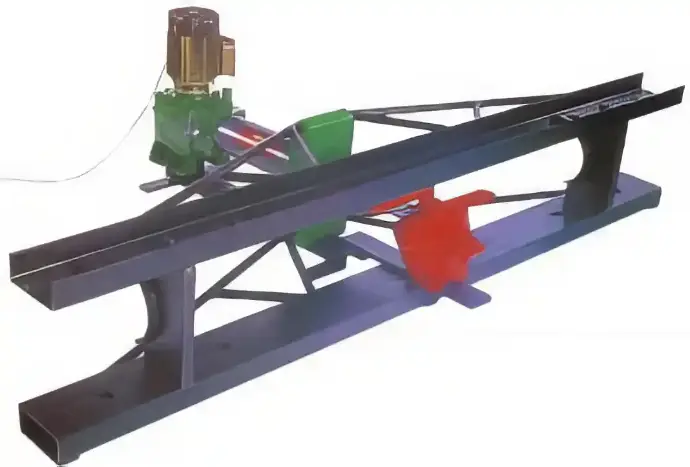

2. Electric bending machines with sliding bracket pair Mingori

The electric version of the bending machine with sliding yoke pair offers increased efficiency and ease of use compared to the manual version. Electrically driven machines are able to work with higher pressure and more consistent precision, resulting in consistent and repeatable bends. Here too, the pair of sliding clamps ensures stable guidance of the material throughout the bending process. Operation is automated, which reduces the amount of work for the operator while increasing production speed.

Advantages:

- Automated control of the bending process

- Greater efficiency and speed

- Suitable for repetitive production tasks

Application:

- Use in workshops and industrial production processes

- Particularly suitable for medium-thickness pipes and metals

3. Bending machines with 180° linkage Mingori

For applications where larger angle bends are required, machines with 180° rods are used. These machines are particularly effective when bending pipes or metal parts into larger radii or even complete semi-circles. The 180° linkage ensures that the material is bent continuously and evenly over the desired angle without damaging the material. These machines are ideal for large-format bending tasks and offer a high level of durability thanks to their robust design.

Advantages:

- High bending angles of up to 180

- Robust design for industrial applications

- Precise and even bends, even with thicker materials

Application:

- Use in the piping and construction industry

- Ideal for large-format metal structures and pipe systems

4. Pipe bending machines for pipeline (coated PEHD pipe) Mingori

Pipe bending machines specially developed for coated PEHD pipes are of crucial importance in the pipeline industry. These machines are designed to gently bend the delicate coated material of the PEHD pipes without damaging the coating. PEHD pipes are often used for drinking water pipes, gas pipes and in the chemical industry, where high demands are placed on resistance and durability. The bending machines for such pipes combine hydraulics and special guide elements to bend the pipe evenly while keeping the coating intact.

Advantages:

- Specially developed for PEHD pipes

- Gentle treatment of the coated material

- High precision and repeat accuracy

Application:

- Use in the water and gas supply

- Ideal for PEHD pipelines in the chemical industry

Conclusion

Hydraulic assembly machines using the pressure bending process are indispensable in modern metal processing and pipe installation. Depending on the application and material, machines with pairs of sliding clamps, 180° rods or specialized pipe bending machines for PEHD pipes offer the right solution. These machines help to increase the efficiency, precision and durability of pipe and metal structures and have become indispensable in various sectors, from industry to construction.