Innovations in tube bending technology: new technologies and trends

Tube bending technology is a key technology in modern manufacturing. Thanks to numerous innovations and technological advances, the efficiency, precision and flexibility of tube bending has improved considerably in recent years. At Tinsel, your partner for advanced tube bending machines, we continuously monitor the latest developments and trends in order to always offer you the best solutions for your production. In this article, we present the latest technologies and trends in tube bending technology that can revolutionize your manufacturing processes.

1. Automation and CNC control

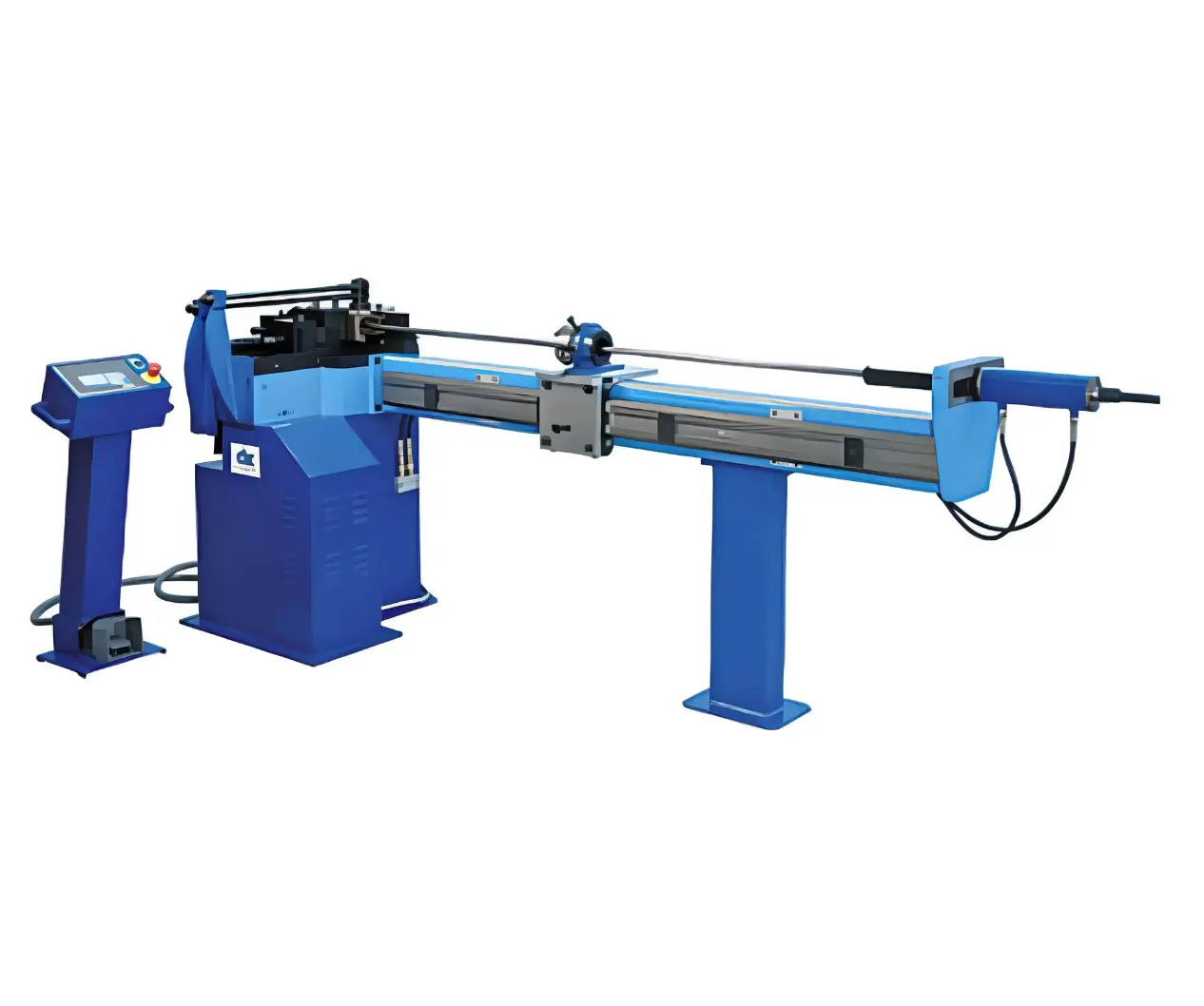

The introduction of CNC-controlled tube bending machines has fundamentally changed the way tubes are bent. These machines enable precise, repeatable and automated control of the bending process, resulting in greater efficiency and reduced error rates.

a) Advantages of CNC control

- Precision and repeat accuracy: CNC machines guarantee exact bends, even with complex shapes and tight tolerances.

- Reduced waste: Thanks to precise control, material waste is minimized, resulting in more efficient production.

- Faster changeover: CNC machines are flexible and can be quickly configured for different bending requirements.

b) Use of automation

Modern tube bending machines are increasingly relying on automation to increase productivity. Robotic arms, automatic loading devices and sensor-based monitoring systems make the entire bending process more efficient and reduce human intervention to a minimum. This is particularly advantageous in series production, where consistent quality and speed are crucial.

2. 3D tube bending: complex geometries in one step

One of the most exciting innovations in tube bending technology is 3D tube bending. This technology makes it possible to bend pipes in three dimensions with different angles and radii in a single pass.

a) Advantages of 3D pipe bending

- Complex shapes: 3D bending enables the creation of tubes with complex geometries without the need for multiple bending steps or weld seams.

- Material and time savings: Avoiding welded joints and additional processing steps reduces the amount of material and time required.

- Greater stability: Pipes that are bent in one step are more stable, as there is no need for weld seams that could weaken the integrity of the material.

3. Simulation and virtual commissioning

Virtual commissioning has found its way into tube bending technology and offers an innovative way of simulating the entire bending process prior to physical production.

a) Advantages of simulation

- Error detection before production: The simulation allows potential errors or material damage to be detected and corrected in advance, before the first tube is bent.

- Optimization of the bending process: Various bending parameters can be simulated to find the optimal process that maximizes material savings and efficiency.

- Shorter development times: Simulation saves time when developing new products, as design changes can be implemented and tested quickly without having to create physical prototypes.

b) Digital twins

Digital twins are virtual images of real tube bending machines that make it possible to monitor and optimize the entire bending process in real time. This technology makes it possible to analyze production data, adjust machines in real time and carry out preventive maintenance work before a problem occurs.

4. Material innovations: Lightweight construction and new alloys

In addition to technological advances, the development of new materials also plays a major role in tube bending technology. Lightweight materials such as aluminum and titanium alloys as well as high-strength steels are opening up new possibilities for various industries, from the automotive sector to aerospace.

a) Advantages of new materials

- Weight savings: Lightweight materials such as aluminum and titanium reduce the overall weight of products, which is particularly advantageous in the automotive and aviation industries.

- Higher strength: High-strength steels allow tubes with thinner wall thicknesses to be bent without compromising structural integrity, resulting in material savings and increased strength.

- Better formability: New alloys offer better formability, enabling more complex bends and tighter radii.

5. Electric tube bending machines: environmentally friendly production

Another major trend is the switch from hydraulic to electric tube bending machines. These machines offer a more environmentally friendly and efficient solution that reduces energy consumption while increasing precision.

a) Advantages of electric tube bending machines

- Lower energy consumption: Electric drives consume less energy than hydraulic systems and therefore contribute to more environmentally friendly production.

- More precise control: Electric machines offer more precise control of bending movements, resulting in greater precision and less material loss.

- Reduced maintenance: Electric machines require less maintenance and are less prone to breakdowns, which extends production times and reduces operating costs.

6. Sustainability as a driver of innovation

Sustainability is a crucial factor in modern manufacturing, and tube bending technology is no exception. Through new technologies such as energy-efficient machines, material optimization and waste reduction, the industry is helping to reduce its carbon footprint.

a) Energy-efficient machines

Modern tube bending machines, such as those available from Tinsel, are designed for energy efficiency. Electrical and automated systems help to reduce energy consumption and increase production output at the same time.

b) Material savings and recycling

By optimizing bending techniques and introducing new materials, material consumption can be significantly reduced. At the same time, recycling processes enable the reuse of waste materials, which contributes to more sustainable production.

Conclusion: The future of tube bending technology is innovative

Tube bending technology is undergoing rapid change, driven by innovations in automation, new materials and sustainable production methods. At Tinsel, we offer you the latest technologies and customized solutions to take your production to the next level. Whether you're in the automotive, aerospace or any other industry, our advanced tube bending machines give you the efficiency, precision and flexibility you need to stay competitive.