Sustainability and resource efficiency in tube bending: optimization potential in modern production

At a time when sustainability and resource efficiency are increasingly becoming the focus of industrial production, tube bending technology also plays a crucial role. Tube bending offers numerous opportunities to reduce the use of materials, minimize waste and increase energy efficiency. At Tinsel, your expert for innovative tube bending machines, we attach great importance to developing machines that are both environmentally friendly and resource-efficient. In this article, you will learn how sustainability can be implemented in tube bending technology and what benefits this brings to your production.

1. Sustainability and resource efficiency - what does that mean?

Sustainability in manufacturing means designing processes and technologies in such a way that they have a minimal impact on the environment while conserving resources. Resource efficiency refers to the economical use of materials, energy and other production resources. In tube bending technology, significant savings can be achieved through optimized machines, improved techniques and the use of sustainable materials - both for the environment and for the company.

2. Resource efficiency in tube bending: How do you save material?

Material savings are one of the biggest advantages that resource-efficient tube bending technology can offer. Precise bending techniques and optimized machines not only minimize material waste, but also reduce production costs.

a) Precise bending reduces material loss

Optimization:

A precise tube bending machine can process the exact amount of material required, so there is no unnecessary waste. CNC-controlled machines offer high accuracy and repeatability, ensuring that the material is bent to the exact desired angle without unnecessary cutting.

b) Reduction of waste through customized solutions

Optimization:

By using customized tools and specialized bending forms, companies can improve accuracy of fit and reduce scrap. This is particularly crucial in industries such as aerospace or automotive, where materials such as titanium or aluminum are expensive and every saving counts.

c) Reusable waste and recycling

Optimization:

In many manufacturing processes, material waste generated during pipe bending can be reused or recycled. This is particularly true for metals such as steel and aluminum, which can be easily recycled without losing quality.

3. Energy efficiency: the key to environmentally friendly production

In addition to resource efficiency, energy efficiency is also an important factor for sustainable tube bending. Modern machines offer a range of benefits that can significantly reduce energy consumption.

a) Energy-saving machines

Optimization:

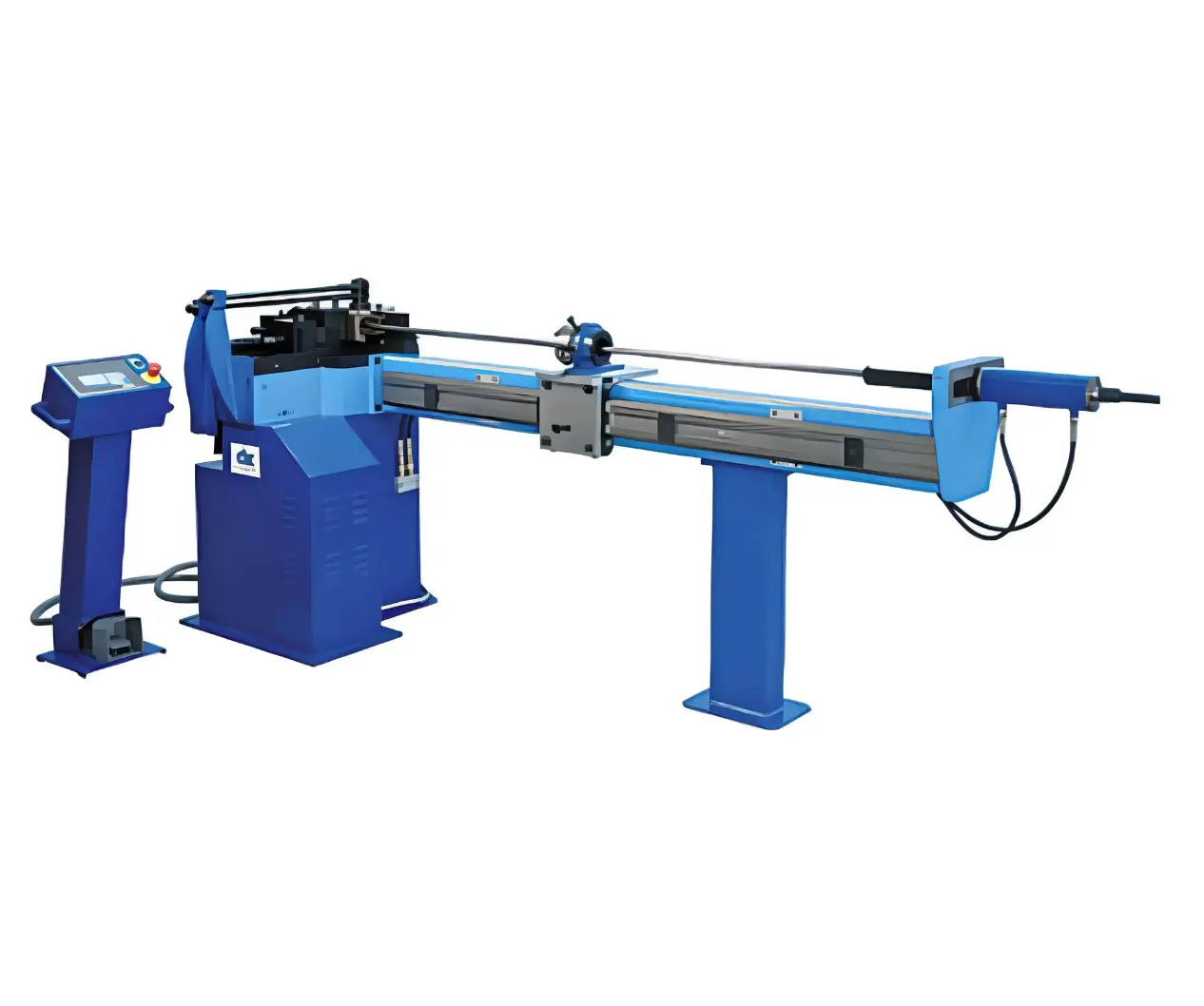

At Tinsel, we offer energy-efficient tube bending machines that are equipped with optimized drives and motors. These machines consume less power and still work efficiently, which not only protects the environment but also reduces operating costs.

b) Automation for less energy consumption

Optimization:

CNC-controlled machines also contribute to energy savings by automating the process and minimizing human intervention. Automated machines are not only more precise, but can also be programmed to optimize energy consumption in real time.

c) Optimized cycle times

Optimization:

A well-tuned machine can shorten cycle times, reducing the time in which the machine consumes energy. This leads to more energy-efficient production overall and shorter production times.

4. Sustainable materials in tube bending

In addition to the resource efficiency of the machines, the choice of materials also plays a key role in sustainability in tube bending technology. Sustainable materials not only help to reduce environmental impact, but often also offer advantages in terms of handling and processing.

a) Use of recycled materials

Optimization:

More and more companies are turning to recycled metals such as steel and aluminum to reduce their use of materials. Recycled aluminum, for example, has a significantly lower carbon footprint than newly produced aluminum without sacrificing quality.

b) Use of durable and corrosion-resistant materials

Optimization:

By choosing durable materials such as stainless steel or special alloys, companies can ensure that products have a longer service life and need to be replaced less often. This not only leads to less material usage, but also reduces the environmental impact of the entire supply chain.

5. Sustainability through longer service life of machines and tools

Sustainability in pipe bending technology also means relying on durable machines and tools that have a long service life and minimal maintenance requirements.

a) Durable tube bending machines

Optimization:

High-quality machines, such as those offered by Tinsel, have a long service life and require fewer spare parts or maintenance. This reduces material consumption over time and ensures more stable production.

b) Maintenance and care

Optimization:

Regular maintenance of machines ensures that they work efficiently for longer and consume less energy. At Tinsel, we offer comprehensive maintenance services to ensure that your machines always remain in optimum condition.

6. Advantages of sustainable tube bending technology

The use of sustainable and resource-efficient tube bending technology brings numerous benefits for companies:

- Cost savings: Less material and energy consumption leads directly to lower production costs.

- Environmentally friendly production: A smaller CO2 footprint improves the company's environmental footprint.

- Competitive advantage: Companies that work sustainably can differentiate themselves on the market and respond to the increasing demand for environmentally friendly products.

Conclusion: Sustainability as a success factor in tube bending technology

The integration of sustainability and resource efficiency into tube bending technology is not only a contribution to environmental protection, but also an important competitive factor. At Tinsel, we offer you modern, energy-efficient machines and customized solutions to make your production more sustainable. Our experts are at your side to develop individual concepts for your company and thus protect both the environment and your production costs.